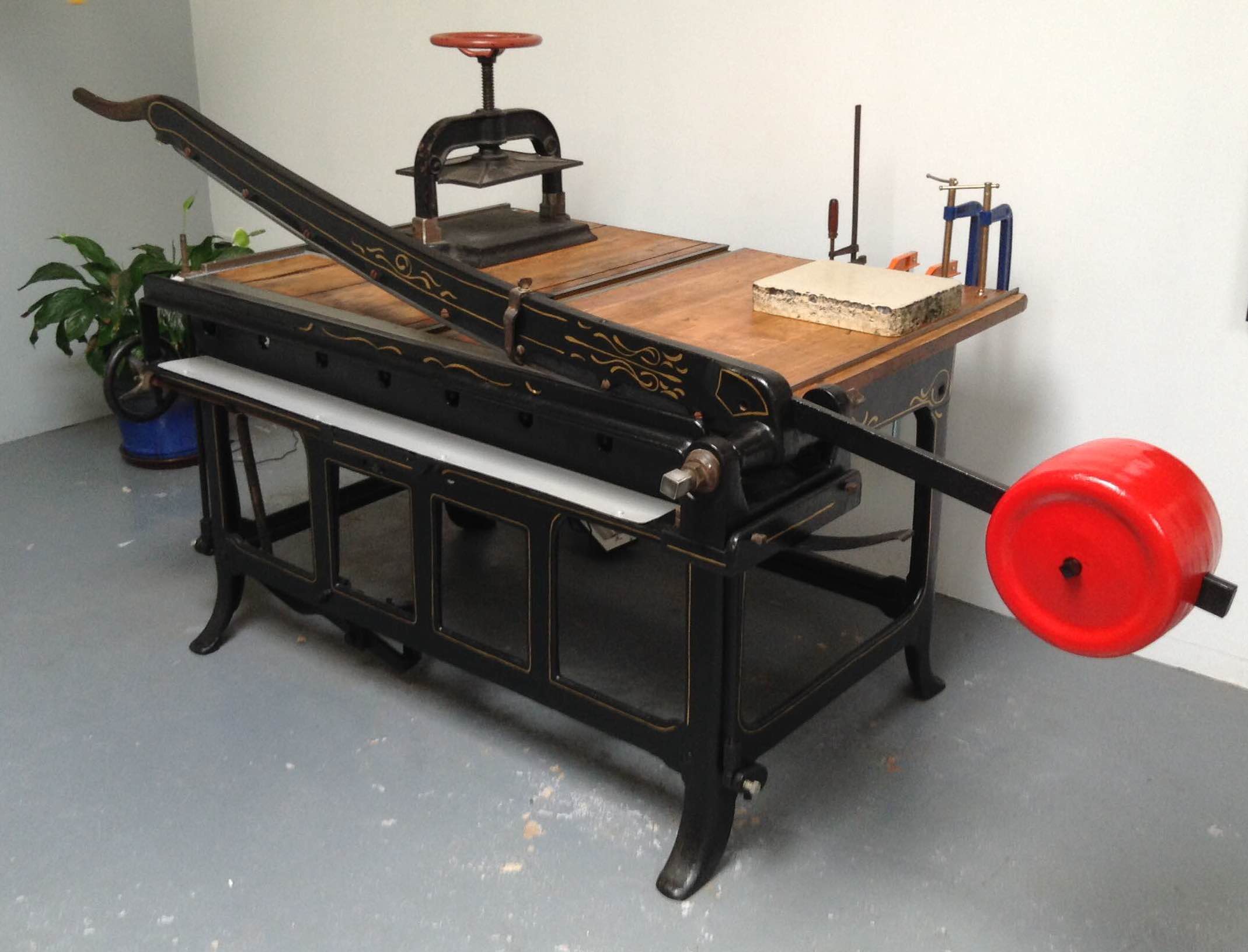

Welcome to this blog series named Tools of the Trade. Like many trades, bookbinding/ restoration has a plethora of tools, which one can really get sucked into. The biggest purchase to date for my bookbinding studio has been 'Elbert' the Board Shear (also known as a board chopper, board cutter). Its main function is to cut binder board, a material often used to make the covers of a book. Before purchasing this beast of a machine I did struggle to cut binder board by hand, this often ended in a cut finger or two and a board that wasn't square.

Board shears by their very nature are very heavy (and from trawling through different sales on the internet- I found to be very expensive). They vary in price from $1,500-$5000. Even on the low end of the price scale this was going to be difficult for my budget. I considered buying a Kutrimmer, (a lot cheaper) which is designed to cut paper, although can be used to cut board - however from experience the board is never quite square and the cut never quite exact.

Kutrimmer

So after looking for one of these machines for over a year I finally saw an ad on Craig's List advertising a 'Paper Cutter' for sale. The photo listing the item was almost non existent and I think it had been advertised on Craig's List for at least two months so I almost didn't call the guy who was selling it as I thought it would be long gone. To my surprise it was still available and located right here in Philadelphia, plus the list price was $500!!!!! I was searching for this equipment all down the East Coast, however shipping costs almost equaled the cost of the machine. I went to take a look - it had been in someone's basement for at least 20 years and the current owner had it stored in his garage (after rescuing it from the basement). He wanted to get rid of it and was quite happy to deliver it to my studio for an extra $100. It was a John Jacques cast iron 40" blade with wooden top, and looked like it had seen better days. However, the blade itself cut like a dream, so I bought it.

As you can probably see from the photos this machine needed ALOT of elbow grease. The blade was pretty rusty, (although just surface rust) so I used wet and dry sanding paper to take off the rust and to my surprise it worked and the blade has a nice silver polish to it. The shear had a wooden top so I sanded that down and treated it with varnish. I painted the cast iron parts of the board shear with a black enamel and per a friend's suggestion I painted the counter weight a bright cherry red - which made it really pop. On the original black cast iron there were some traces of gold decoration so I paid a local sign writer to re-paint this gold decoration on top of the black enamel. I wanted to keep a lot of the original features - or at least bring them back to life. I did have to buy a new back gauge which keeps the board straight while measuring the piece of binder board but this was a worthwhile investment. Whenever I chop a piece of binder board it is now always the exact measurement I want - down to the millimeter.

Oh - and I named the board shear 'Elbert' because the guy I bought it from was called Elbert (quite an unusual name I thought).

In my next post I'll talk about other board shears, their histories and functions.